More Guides

Change Bambu Lab Nozzle Size (Alternative Hotend)

A wide range of alternative hotend options have become available for 3D printing enthusiasts. The stock hotend often lacks a swappable nozzle feature, meaning you’d have to replace the entire hotend assembly if the nozzle needs changing. However, if you frequently print with different filament materials or perform numerous print jobs, a swappable nozzle hotend can be an extremely convenient upgrade.

Benefits of switching to an alternative hotend:

- Swappable Nozzle

- Higher flow rate

- Cost savings

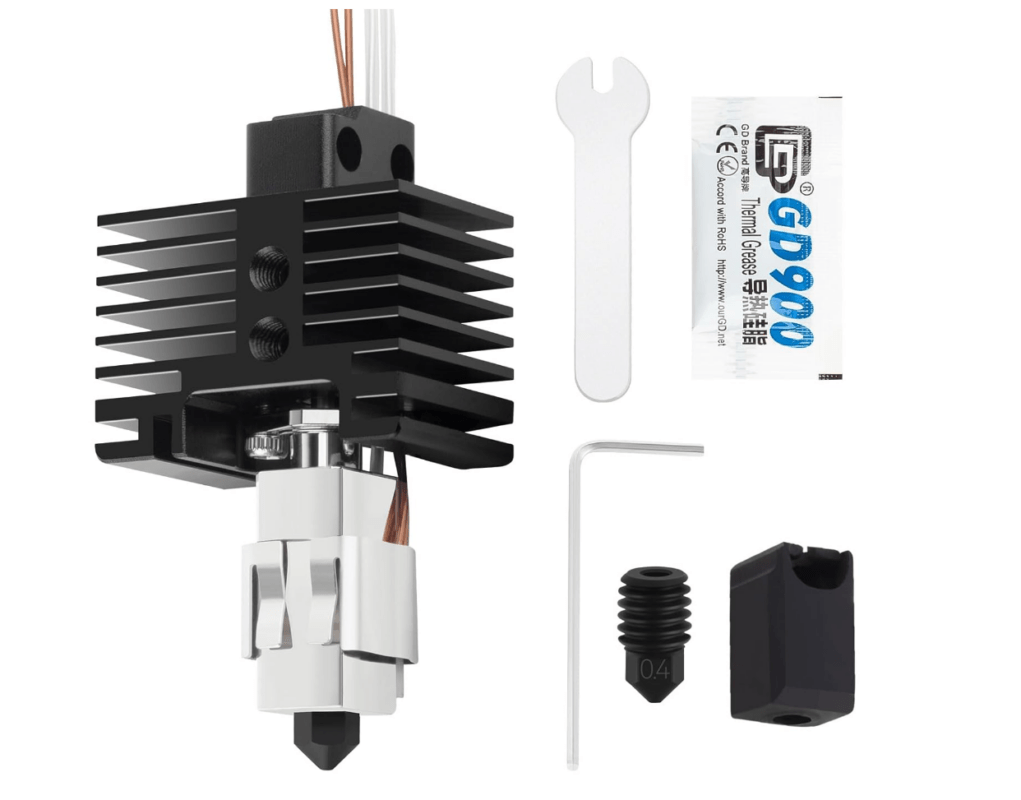

Bambu Lab Hotend TZ 2.0

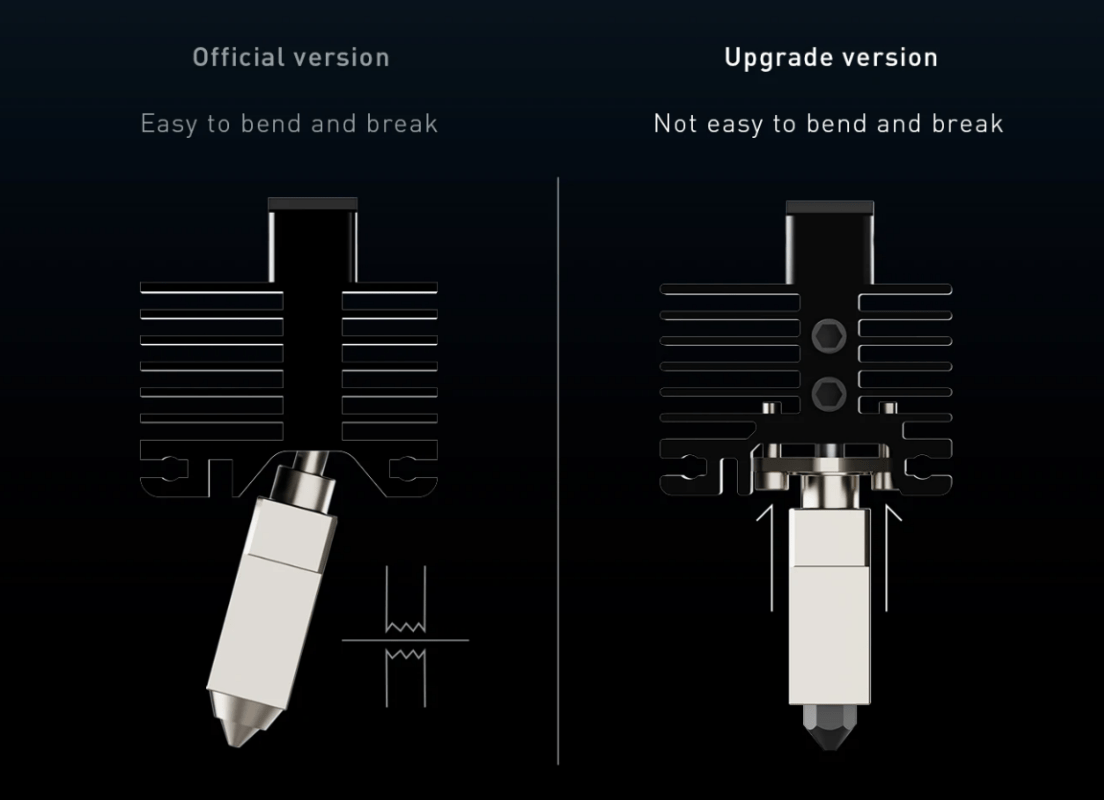

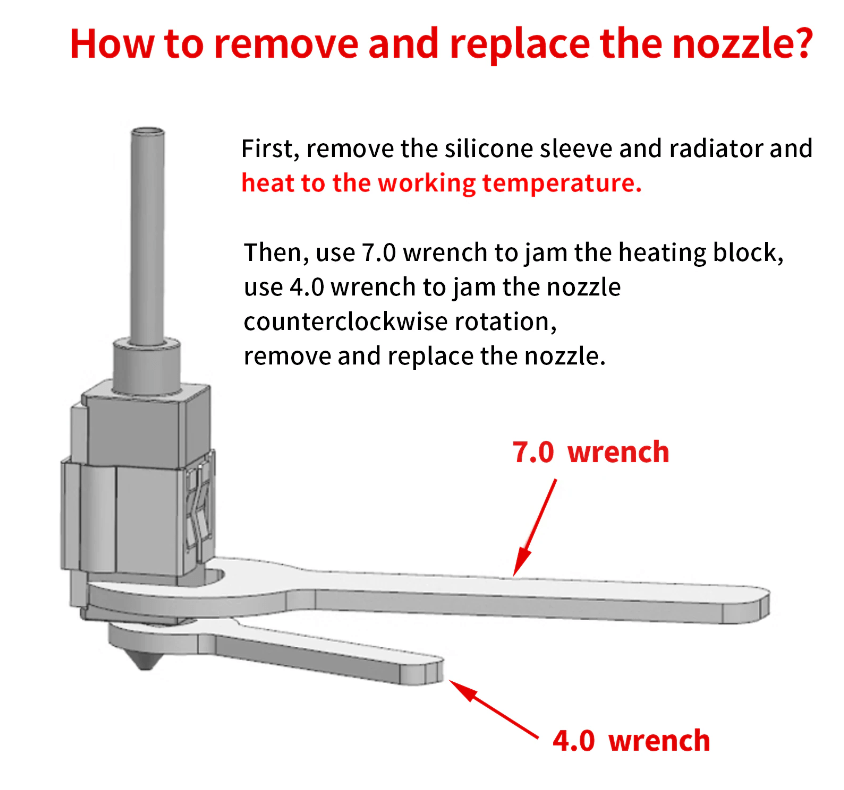

One of the latest alternatives is the TZ 2.0 hotend. Not only does it allow for removable nozzles, but it also has an extra screw to prevent the hotend from bending in case of failure. In the long run, the cost of this hotend is significantly lower.

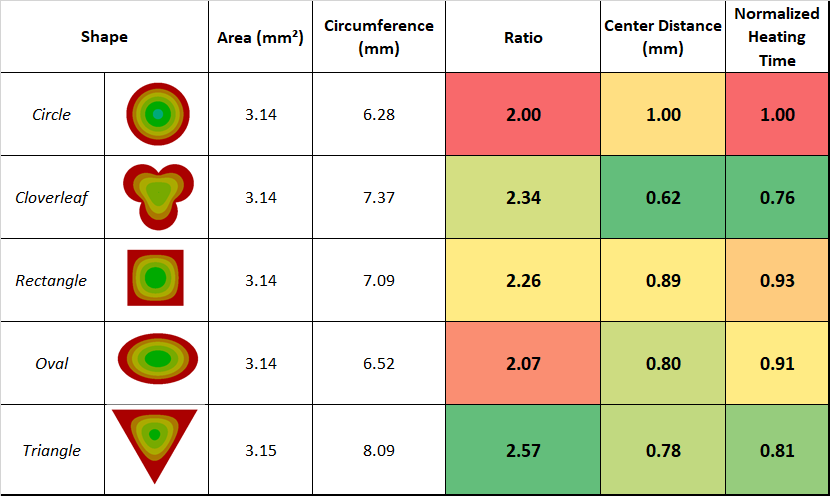

Nozzle Upgrade: CHT High Flow Nozzle

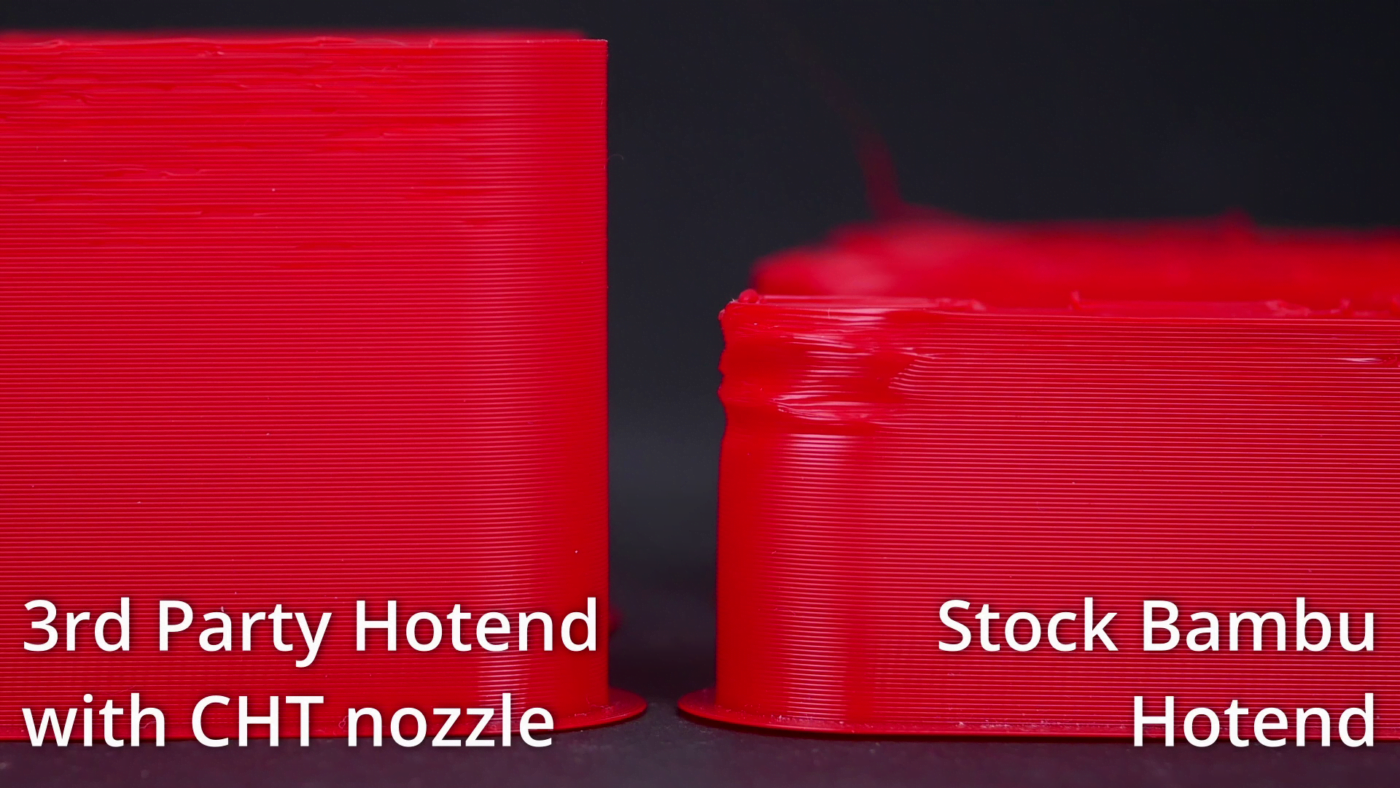

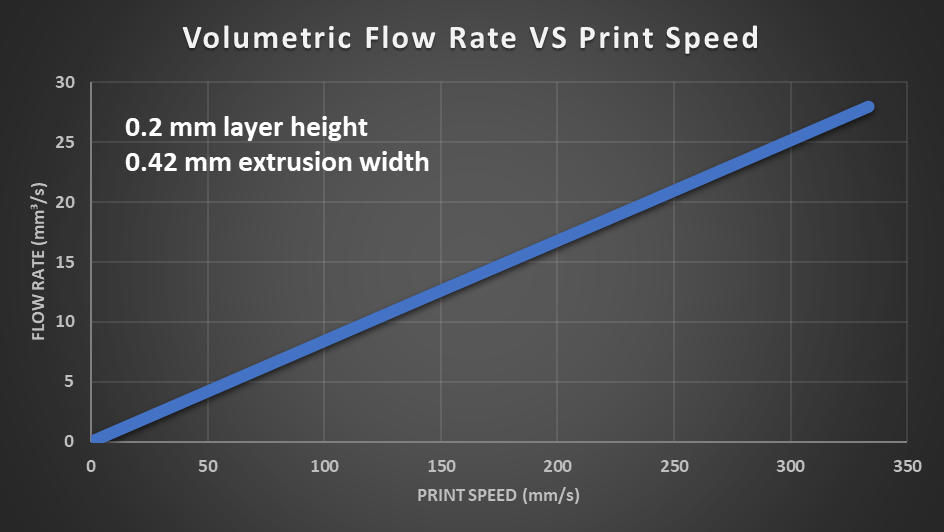

By using a custom hotend, you can swap to high-flow CHT nozzles. The below picture shows a single-walled part printed in vase mode. As the print progresses, the printing speed increases. You can see that the CHT nozzle can still perform well at a 40mm flow rate. This effectively reduces the likelihood of under-extrusion during printing, helping to prevent failures and save costs in the long run.

Prints produced at high speeds using the CHT nozzle exhibited noticeably improved strength and resilience, with layers adhering firmly together without separating. If maximizing your machine’s performance is a priority, investing in a replacement hotend and installing either a Bondtech or the custom CHT nozzle could be a worthwhile endeavor. These nozzles enable you to extract every ounce of capability from your 3D printer.