Firmware & Guides

3D Printer Filament Grinding : Common Solutions (Updated 2021)

- What causes Filament Grinding & Stop Extruding mid print?

- Grinding Solution 1: Loosen the screws around your extruders

- Grinding Solution 2: Reduce retraction settings

- Grinding Solution 3: Increase Hotend Temperature & Reduce Printing Speed

- Grinding Solution 4: Clean up the dusty gear

- Grinding Solution 5: Nozzle Clogging

- Alternative Solutions: Extruder Upgrade

- Additional Articles Related Filament Grinding

What causes Filament Grinding & Stop Extruding mid print?

Most 3D printers uses one of two small drive gear to grabs the filament and pressed it against another bearing. The drive gear has sharp teeth that allow it to bite into the filament and push it forward or backward, depending on which direction the gear spins. If the filament is unable to move, yet the drive gear keep spinning, it can grind away enough the plastic from the filament so it will be stripped & causes clogging.

Grinding Solution 1: Loosen the screws around your extruders

Take a look at the filament after it passthrough the filament, if it looks bad, it gonna be worse when it’s under go retraction. The very first thing to do is make sure the screws round the gear is loosen so filament won’t be sandwiched too hard.

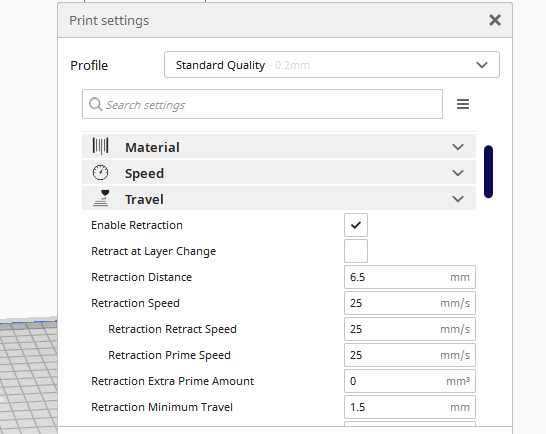

Grinding Solution 2: Reduce retraction settings

If loosing the gear does not help, you may try reduce the retraction settings. Retractions happens when your hotend trying to travel to one place to the another, it withdraw the filament from the hotend, and minimizing ooze and stringing. However if retraction settings were too aggressive, it causes filament grind repeatedly and break around the extruder. Certain complex model has more than 100 retractions on a same layers, it will definitely cause breakage of filament in long run.

Teaching tech has a very good retraction tower gcode for you to print & test. https://teachingtechyt.github.io/calibration.html#retraction

At the end, take the shortest & slowest with minimal or no stringing.

Grinding Solution 3: Increase Hotend Temperature & Reduce Printing Speed

Sometimes increasing the hotend temperature by 5-10 degrees so that the filament may flows easier. When it flow easier, less force needed for extruder to push & filament won’t be stuck easily.

If still encounter filament grinding, you should decrease the printing speed. When printing speed is fast, extruder drive gear is spinning fast & generating heat. Low temp material like PLA may be soften & may bend & stuck around the extruder. Try to reduce the printing speed by 30~50%, see if it’s helps.

Grinding Solution 4: Clean up the dusty gear

Many times after long prints, dusts & filament residue may build up around the extruder gear. This may stop the extruder working as effectively as it should and causes slipping. If your prints work at first then slowly start failing, this could be the reason.

Simply blow to the extruder to displace the dust. If the dust or filament still stuck in between the nozzle, get a nozzle brass brush and simply brush off the residue around the nozzle. or whatever tools that’s not abrasive enough to scratch your extruder.

Grinding Solution 5: Nozzle Clogging

If above solutions still not working, then it’s likely your nozzle is partially clogged. Please read the clogged hotend section for instructions on how to troubleshoot this issue.

Alternative Solutions: Extruder Upgrade

A good upgrade to any 3D printer is changing the extruder. Most of the stock extruders is made of plastic & can crack or generate all kind of extrusion issue. But when upgrading, please take note that most upgraded extruders are taller & you may need to move your mount or even filament sensor to a higher position..

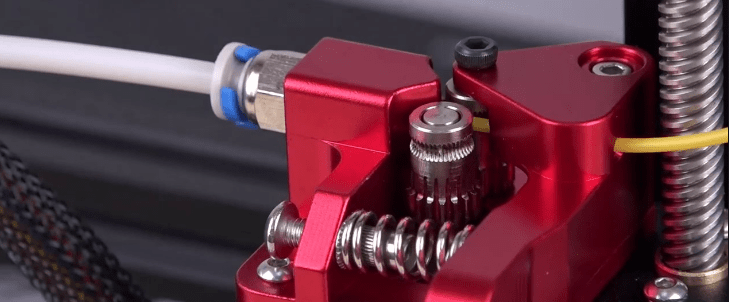

Dual Gear Extruder

Dual gear extruder uses two drive gear which grips the filament from both sides increasing the control and the performance of the extruder. Since it’s made of metal, it won’t be crack and much more long lasting compared to the stock.

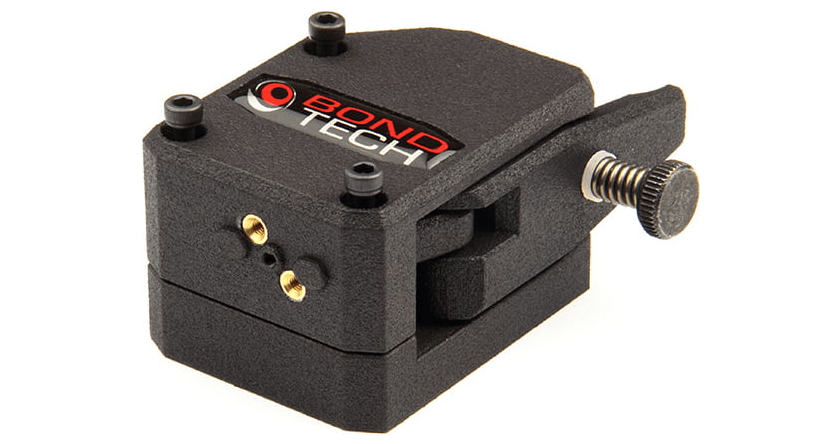

BMG Extruder

BMG is another really good extruder around. Same as dual g ear extruder which is using two drive gears to grip the filament, It also offer 3:1 gear ratio which can run much quieter & on pancake motor. The arm is also very flexible and can adjust easily.

Additional Articles Related Filament Grinding

If you can’t get enough of filament grinding info here, do check the pages as they provide a lot helpful info

- https://www.simplify3d.com/support/print-quality-troubleshooting/grinding-filament/

- https://3dprinterly.com/why-is-my-extruder-grinding-the-filament-causes-solutions/

OK, let me start from the beginning. Several weeks ago I had a thermal runaway on my Ender 3. Turns out the thermister (glass bead at the end) broke. So I replaced the thermister and since then I gave had failure after failure. I kept getting extruder knocking and the print would fail. I noticed there was some wear on the extruder gear so I just went ahead and upgraded the extruder and the Bowden tube, so now all parts are replaced. But I still had gear grinding. So after doing more online research I thought maybe the thermister was giving me a wrong temp reading and the hot end wasn’t keeping up with the filament. I was running PLA+ at 200c and 100% speed. I slowed the speed down and increased the temp at 5 degree increments. Still I had gear grind. Well it turns out the thermister was indeed giving me the wrong temp, but it was the other way! I was running way too hot and was getting heat creep in the tube. I lowered the temp to 185c and increased the speed to 110% and the print is absolutely perfect.

This was a frustrating experience for me but I learned a lot my 3d printer. So don’t get discouraged, keep plugging away. I hope this helps someone avoid the hair pulling I went through.