Getting Started, Upgrades & Maintenance

eSUN Matte PLA Printing Problems & Solutions

Problem #1 – Clogging, Stringing or Signs of Under/Over Extruder

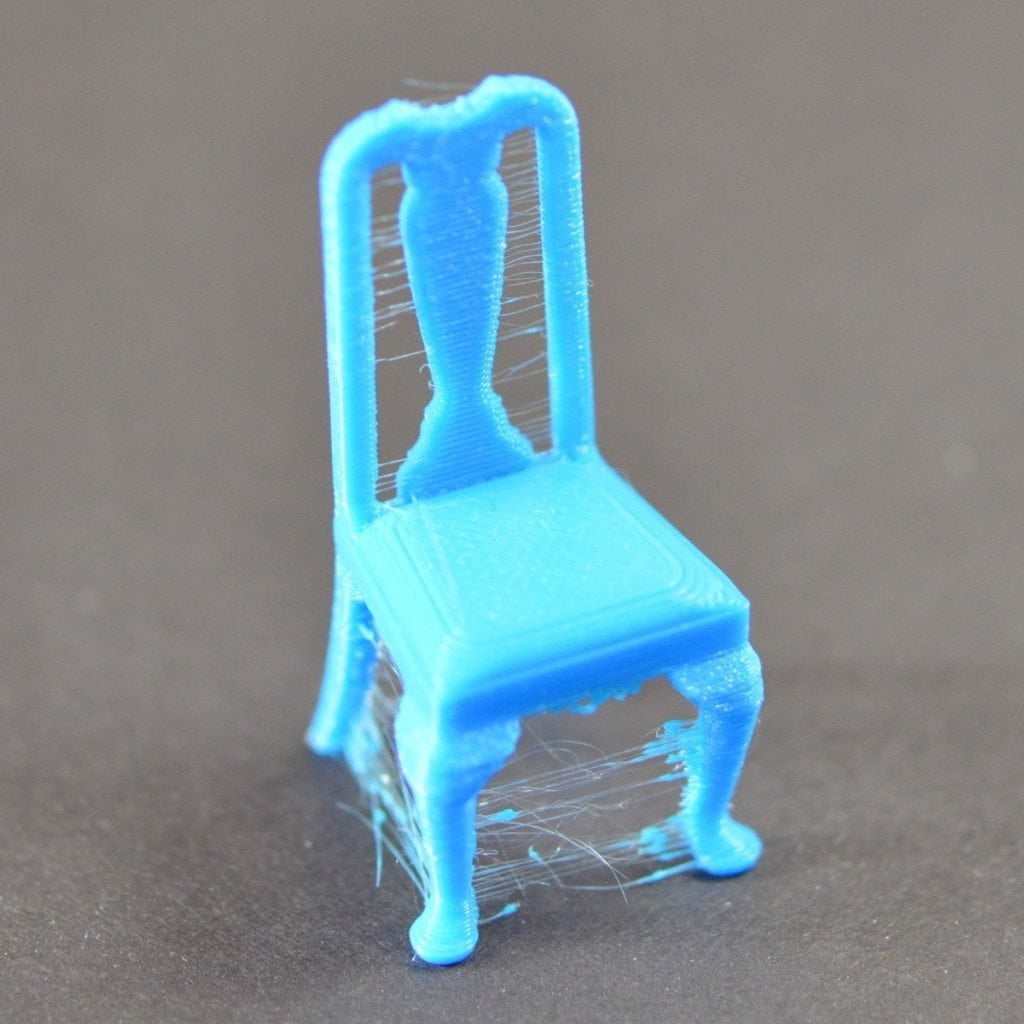

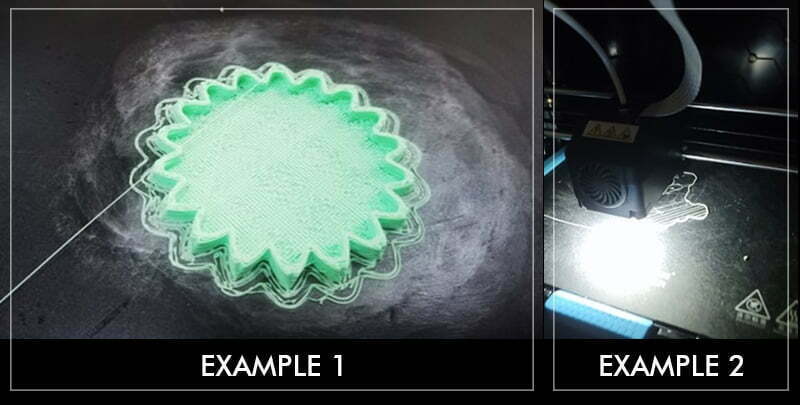

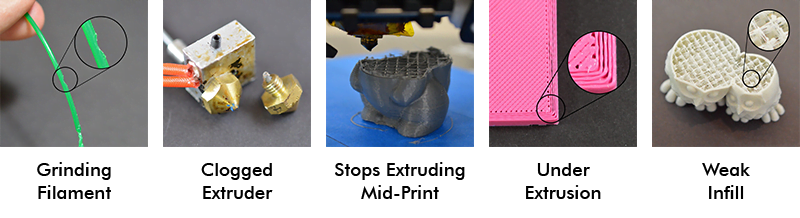

Examples of this problem can be seen in the pictures below:

Recommended Solutions

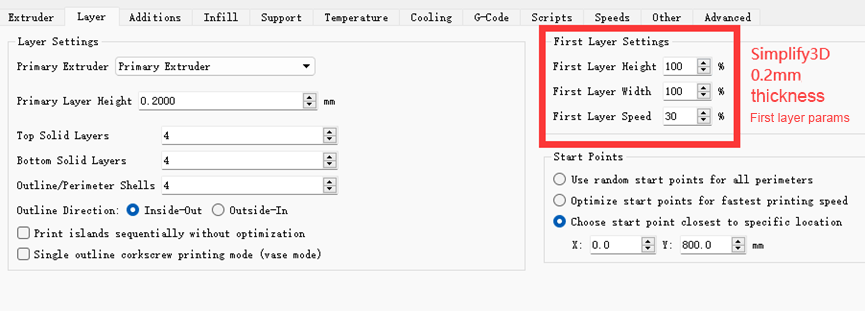

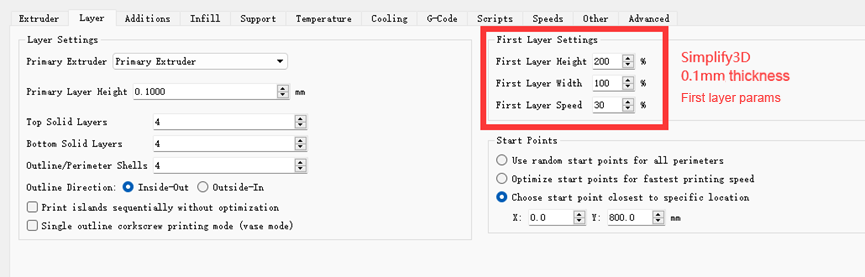

- Increase the nozzle temperature to 230°C, lower down the print speed to 40mm/s, reduce the first layer height to 0.1mm to see if it can be printed without any issue.

- If issue still persists, remove the PTFE tube from the hotend, and check the end of the hotend for any filament residues or even burnt signs. This could mean that the PTFE tube is wearing out and needs to be cut off or replaced. When replacing PTFE tube, ensure that you are operating under preheated condition. Also, do make sure there is no gap between the PTFE tube and the nozzle. Swap out the nozzle if it’s wearing out.

- Check whether the extruder gear is gripping too tight. If there are sign of filaments residue around the extruder gear, try to loosen the extruder spring. Learn more in filament grinding article.

Problem #2 – Not sticking to the Bed / Warping around the Corner

Recommended Solutions

- Try to relevel the bed, and adjusts it so that it is not too near nor too far from the bed. If four corners’ gaps are too huge, there’s a high chance where one corner will be warped.

- Adjust the slicing setting – on the initial layer, set the flow rate more than 100% (maybe 110/120%), then initial layer speed set to 10mm/s. Turn off the initial layer fan and set the bed temperature to 45-60C. If condition worsens, you can set Brim or Raft in the adhesion setting to increase the adhesion to the bed.

3. If the above solution could not solve the issue, try to use PVP Glue Stick or hair spray to increase the adhesion of the filament to the bed. If glass bed coating is wearing out, you may change a new glass bed to increase the adhesion.

4. If the room temperature is too cool, PLA filament may warp easily. Make sure the difference in room temperature vs bed temperature is not too huge.

Problem #3 – Stringing

Recommended Solutions:

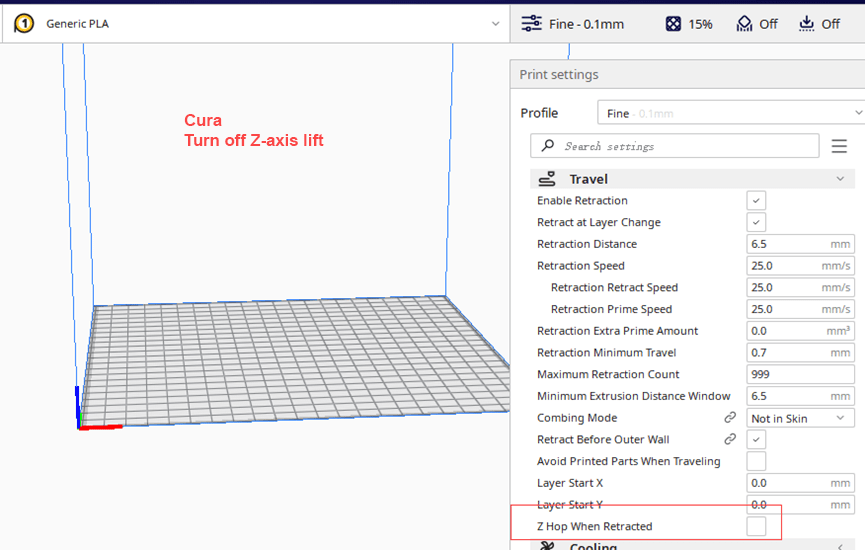

- Improve the retraction distance & retraction speed in your slicer setting.

– If retract too far, it could cause under extrude or even filament grinding.

– If retract too short, it will get stringing easily. Try to print retraction tower and find the best result for the filament.

2. The higher temperature, the easier stringing will occur. It is recommended to lower the temperature down to the lowest recommended temperature of the filament.